-40%

SMT Pick and Place Machine CHMT-550 4 Heads 50 Feeders Auto Nozzle Change

$ 5586.24

- Description

- Size Guide

Description

Welcome to be the distributor of our machines in your country! for more details. please feel free to contact us!Perfect High Accuracy Ball Screw CHM-550 Desktop 4 Heads 50 Feeders SMT Pick and Place Machine (with Auto Nozzle Change) for SMT Batch Production

New updated model by Charmhigh 2022, high precision, high configuration.

Room saved, very good for small batch production with high stability.

Introduction:

1. Model number: CHM-550

2. Brand: Charmhigh

3. Main configuration: High precision 0201 + 4 heads 50 feeders + Desktop type + Ball screw with & linear guide + Servor motor + 7 cameras + Yamaha feeders supported

4. Max PCB area: 400*300mm

5. Component: 0201, 0402-5050, SOP, QFN, QFP, BGA etc.

6. Dimension: 980mm(L)*1050mm(W)*880mm(H), AC220V/110V (50/60Hz)

7. Lead time: 5-7 working days

8. Delivery: by DHL door to door, by air, by sea, or pick up from our factory, or ship to shipping agent

9. Payment method: wire transfer (T/T); PayPal; credit card; W/U

10. Packing: plywood box

11. HS code: 8479.89.62.00 (Pick and place machine)

Description:

This is an updated model from Charmhigh, it has high configuration and higher preicision, if you want a high precision machine, this one is your best choice!

Welcome inquiry, please send us E-mail if you have any more questions.

Specifications:

Charmhigh CHM-550 Specifications

Dimensions

980(L)x1050(W)x880mm(H)

Weight

190kg

Power Supply

AC220V (50Hz, single phase), 2.1kW

Air Supply

0.5MPa ~ 0.6MPa

Vacuum Generation

Japan PISCO vacuum generator

Mounting Head

4 Heads

Mounting Speed

6000cph(optimal)

Mounting Accuracy

±50μm@μ±3σ/chip

Control Accuracy

5μm

Component Height

12mm

Component Type

0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.)

PCB Thickness

0.6mm~3.5mm

PCB Size

400mm(L)x300mm(W)

PCB Delivery

Manually

Nozzle Change

Automatic nozzle change (13-hole nozzle library)

Control System

Built-in industrial computer (Windows system)

equipped with monitor, keyboard, and mouse

Drive System

X&Y axis driven by servo motors; adopting

flexible S-curve acceleration and deceleration

Transmission System

Ball screw + linear guide

Feeding System

50 Yamaha

8mm standard

pneumatic/electric feeder slots

(also suitable for IC

tray + stick/tube/vibration feeder)

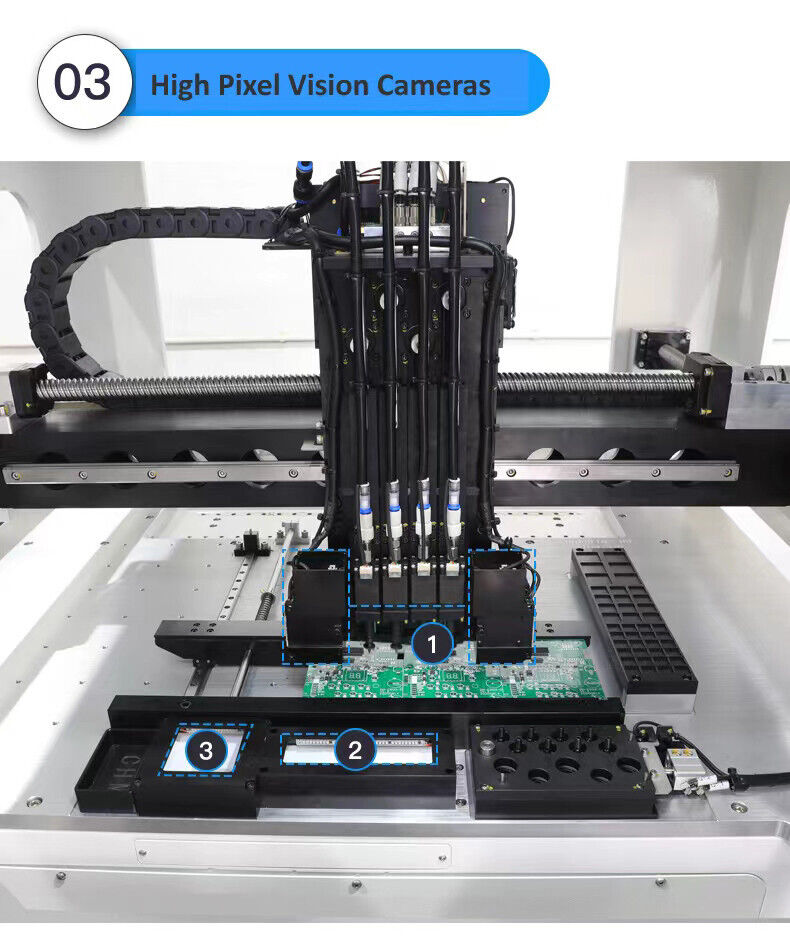

Vision System

Snapshot camera x 4 (component size applicable: 14mmx14mm);

IC camera x 1 (component size applicable: 25mmx25mm);

Mark camera x 2

This is CHM-550 photos:

Advatnages of CHM-550:

This is a high precision model , very good for IC

100% Real photos:

Comes with whole set computer:

PCB samples from customers:

Kindly note:

The CHM-550 smt pick and place machine only need to connect external air source which is prepared by yourself, no need other stuff.

The machine has passed QC passed before ship out.

We provide timely after-sales service, each machine 100% tested well before ship out. Please purchase it with confidence.

Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% tested well before ship out.

、

Accerrory list

We also have models by below:

Maintenance:

Clearing machine after using, close software before switch off power;

According to condition of using, smear some grease to bearings regularly to make sure it work smoothly.

Cover machine if unused for a long time to avoid the dust.

Warranty:

Warranty range: SMT machine itself.

Warranty period: 12 months.

If there are problems in using, please contact us promptly, and do not repair by yourself to avoid damage to machine, or will lose your warranty.

If accessories are breakdown, we will send a new one to you after receiving the break one.

During warranty period, freight of send back to us is paid by user, freight of send to user is paid by us

RETURN POLICY

Your satisfaction is our first priority. Defective product will be offered for an exchange or store credit. and if you want a refund. please you have to return the machine back to us on buyer pay for the shipping cost.

It is buyer's responsibility to contact us within 30 calendar days of receiving a defective product. Otherwise, no replacement or refund will be made. All items MUST be returned in their original condition.

The original Shipping and handling charges are not refundable.

Buyer is responsible for shipping and proof of delivery on all returns.

Upon verification of any faults of the returned item, we will reimburse the postage of return and send you a replacement item within 48 business hours.

We will take care of the cost to send the replacement item to you.

Provide one to one after-sale service.

Each machine 100% tested well before ship out

Factory and exhibition

CE CERTIFIATIONS:

Thanks!

On Apr-12-22 at 03:53:18 PDT, seller added the following information: